Home page

SMART PAINT SYSTEM

| ||||||||||||||||||||

|

| ||||||||||||||||||||

| Details | ||||||||||||||||||||

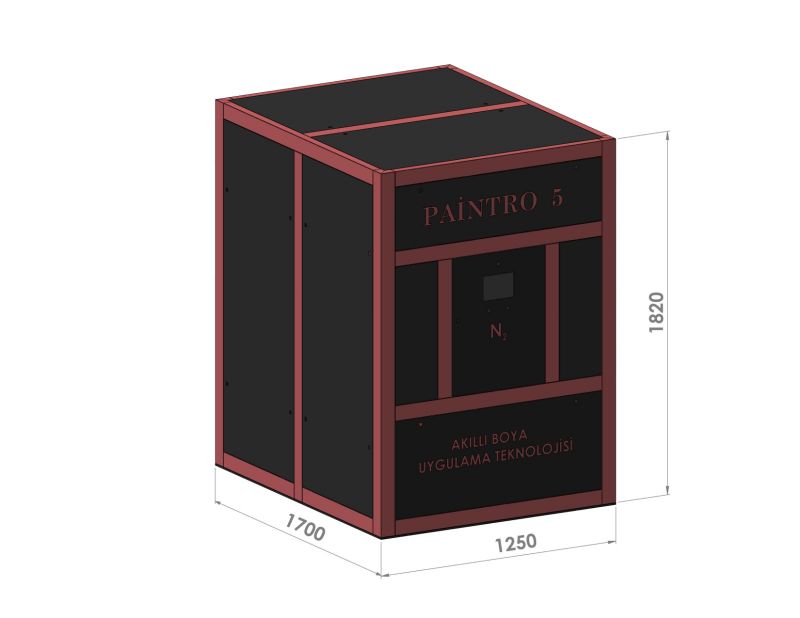

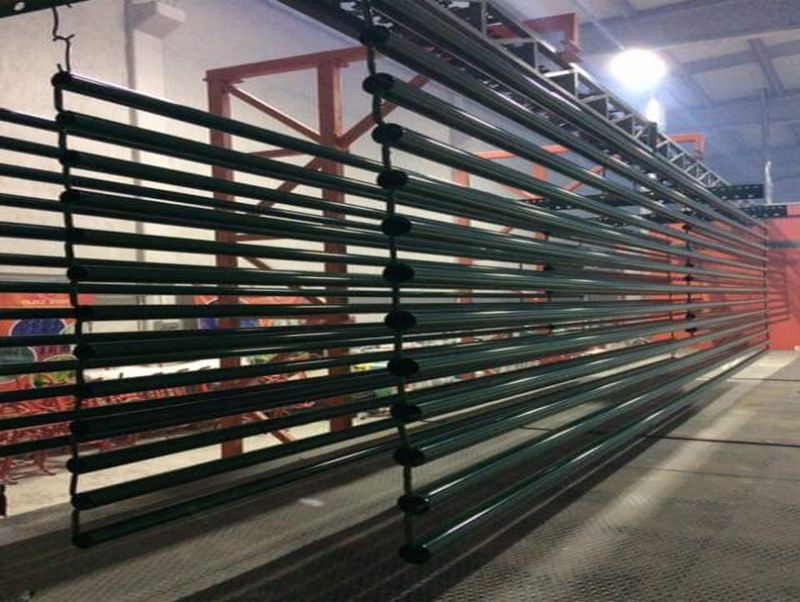

PAINT SAVINGReduction of dusting system, increase in adhesion due to better paint loading, combined paint savings obtained by equal paint spread, saves paint between 10% and 30% regardless of brand, model and facility. ORANGE SHELL EFFECTBecause gas generated by paintro is a lighter and quicker gas, it gives the reaction of going forward with respect to air under the same pressure. that’s why, it is necessary to pull our guns back and its biggest gain is that paint sprayed from a distance also decreases the ratio of orange peel. ECONOMICEven if you have a drying system in paint sprayed with air, you spray paint with the moisture ratio of +3 0c at minimum. while it prolongs maintenance period by shortening consumable material life of your moisture gun, it also moisten paint and it means not re-using when paint is taken back from recycle. Because there is no moisture in paintro, firstly there will be an increase in consumable material lives and secondly a profit will be made by regaining paint from recycle POWDER REDUCTIONOwing to less dusting in paint spraying with paintro, profit made by decreasing amount of the paint poured furthermore, labor profit by providing recovery from re-cleaning time of paint going inside and around cabin BETTER LOADINGWhen we load the paint with 100 units of air, the 21% oxygen contained in the air draws onto the surface we paint by pulling on the electron particles. In Paintro system, it increases the paint adherence by increasing the paint adherence to the surface by making 100% loading to paint and provides paint saving. STATUS FORECASTReducing the amount of oxygen in the environment with the Paintro paint application system provides a reduction in the risk of explosion. SECOND COAT OF PAINTPaintro staining also minimizes the risk of disease because the risks of this miniature static jump are minimized. SURFACE DISTRIBUTIONIt was observed that the micron thickness difference in the measurement made on the general flat surface of the paint thrown by Paintro decreased to +/- 5 microns difference.

PAINT STORAGE STATUS: 1Decrease in dusting in store was observed as of starting of boiling paint store with paintro. furthermore, paint boiled became drier and more fluid because there is no humidity in gas generated by paintron. thus, it provides homogenous expansion of paint on the surface. every paint that doesn’t dust is ours as saving. PAINT STORAGE STATUS: 22nd and one of the biggest benefits is that paint is comfortably useful for the next time by hiding like the first day after taking back from store to change color. paint boiled with air doesn’t have the same perofrmance if it is wanted to be used on next days. PAINT STORAGE STATUS: 33rd benefit is that there is no flocculation in paint store as a result of boiling with paintro. therefore, it completely removes obstruction because dusts of paint flocculated don’t go through injectors of the guns. every paint that doesn’t dust is ours as saving.

OXYTECHOXYGEN GENERATOR Ways to Supply Oxygen

Technical KnowledgePressure swing adsorption processes utilize the phenomenon of gases being attracted or "adsorbed" to solid surfaces under high pressure. The higher the pressure, the more gas is absorbed. When the pressure is reduced, the gas is released or deformed. Your FocusIt should be to eliminate your dependence on the outside by producing the oxygen you need yourself. Benefits of Generating OxygenThere will be no oxygen purchase costs. There will be no loss of manpower for purchasing processes and no loss of operator workforce in changes. There will be no delays due to deadlines. Accidents and risks that may be encountered during changes on the OHS side and during transportation will be eliminated. Medical ProficiencyIt has the Medical Devices Directive 93/42 / EEC certificate. Medical Devices Quality Management Systems has EN 13485: 2016 certificate . It provides the production of medical oxygen gas according to the European Pharmacopoeia standards. Occupational Health and Safety Management System has TS ISO 45001: 2018 certificate. It has Good Manufacturing Techniques GMP certificate. Has Quality Management System ISO 9001: 2015 certificate Medical OxygenWorking 24 hours a day, 365 days a year Touch screen controlled Fully automatic operation Oxygen production with 93% sensitivity in compliance with Medical Standards Resistant to heavy working conditions Low energy 24/7 service support Container type production

| ||||||||||||||||||||